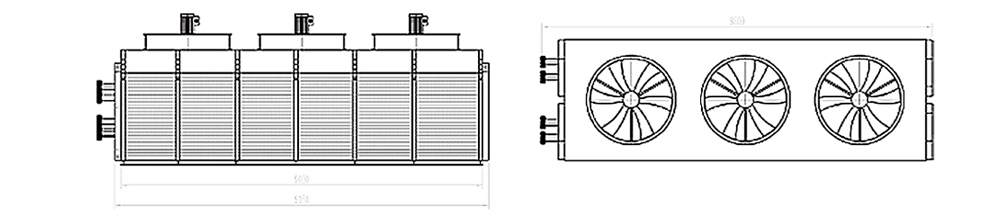

CASEN BRAND GOOD QUALITY CUSTOMIZED DRY TYPE ADIABATIC INDUSTRIAL AIR COOLERS

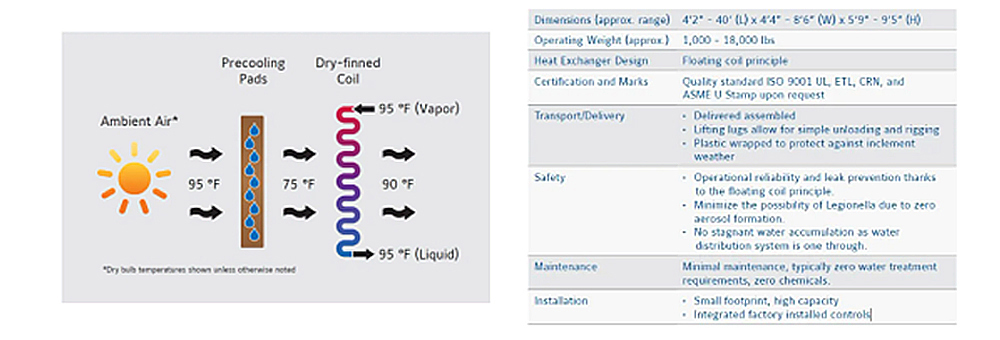

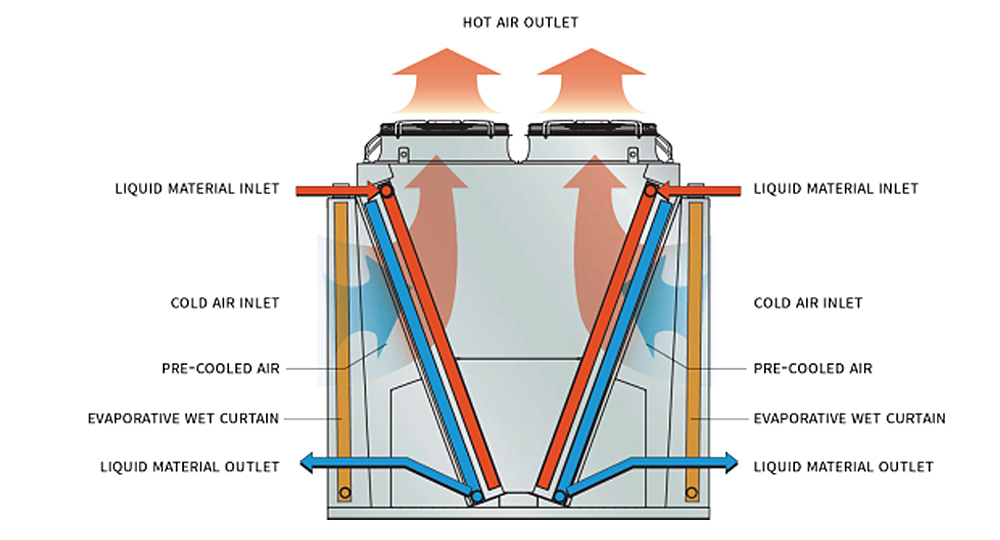

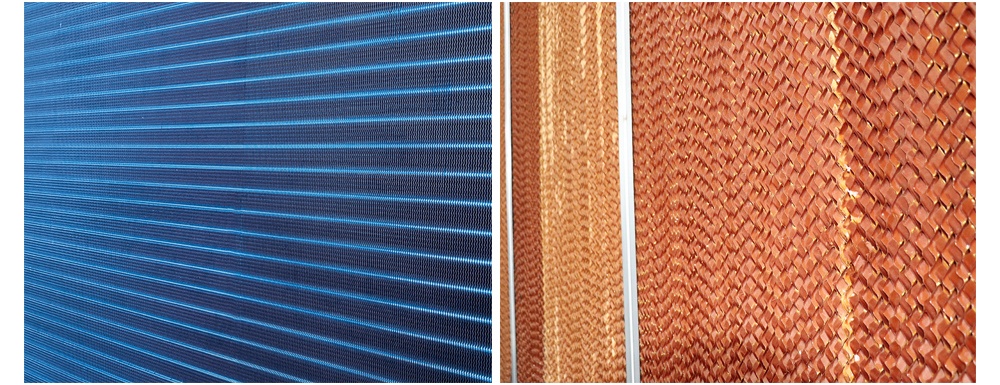

The function of the Adiabatic Efficient Air Cooler is similar to that of the dry air cooler system, but an evaporative wet curtain is added. The water flows through the evaporative wet curtain, and the air sucked into the unit also passes through the evaporative wet pad. At this time, the adiabatic cooling process occurs when a reduction in the pressure within a system causes a volume expansion, resulting in “work” on the surrounding environment. The dry bulb temperature of the inlet air is reduced. The reduced dry bulb temperature gives the unit greater heat rejection capacity.

ADIABATIC OPERATING PRINCIPLE WET OR DRY OPERATION

Efficient FACS adiabatic condensers with hydroBLU™ Technology can be operated either wet or dry. Both modes provide excellent performance with a small footprint and low operating costs.

HIGH THERMAL EFFICIENCY

Increased Thermal Performance, Lowers Total Cost of Ownership At peak ambient temperatures, the air entering the finned heat the exchanger is pre-cooled by wetted cooling pads to a temperature approaching the wet-bulb temperature, without the aerosol formation and without applying water to the finned surface.

The pre-cooling process maintains the required condensing temperatures at peak ambient conditions. The adiabatic process significantly increases the thermal efficiency of the condenser with minimal water usage.

The increased thermal performance at peak ambient conditions lowers the total cost of ownership. The reduction in compressor energy usage permits higher COP's, with a significantly reduced footprint.

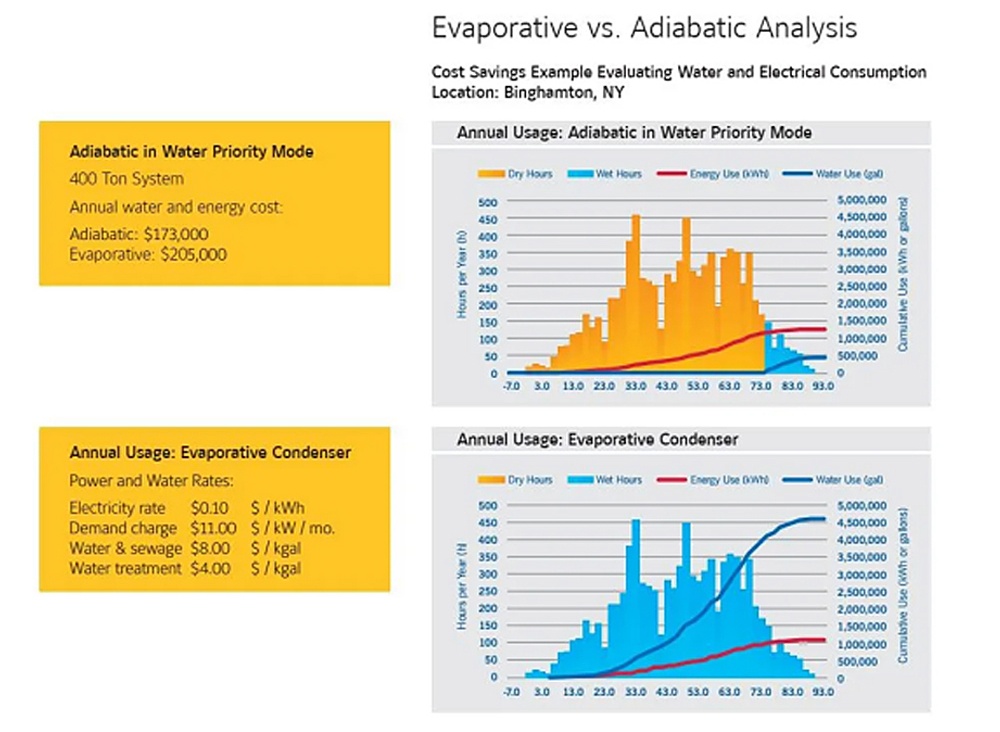

Evaporative condensers use water as the evaporative cooling source throughout the year. The adiabatic alternative only uses water at peak ambient conditions thereby significantly reducing or eliminating water usage, water treatment, chemicals, sewage, and the costs associated with each.

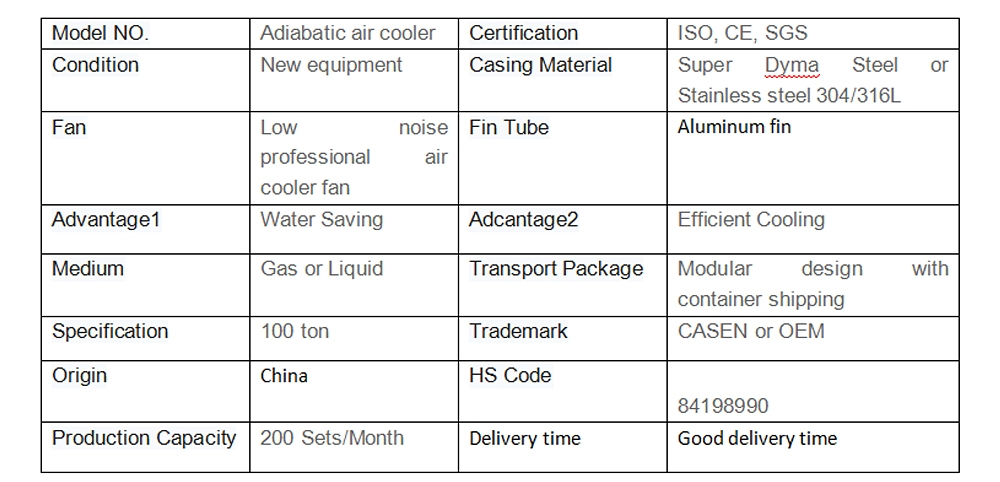

TECHNICAL DATA

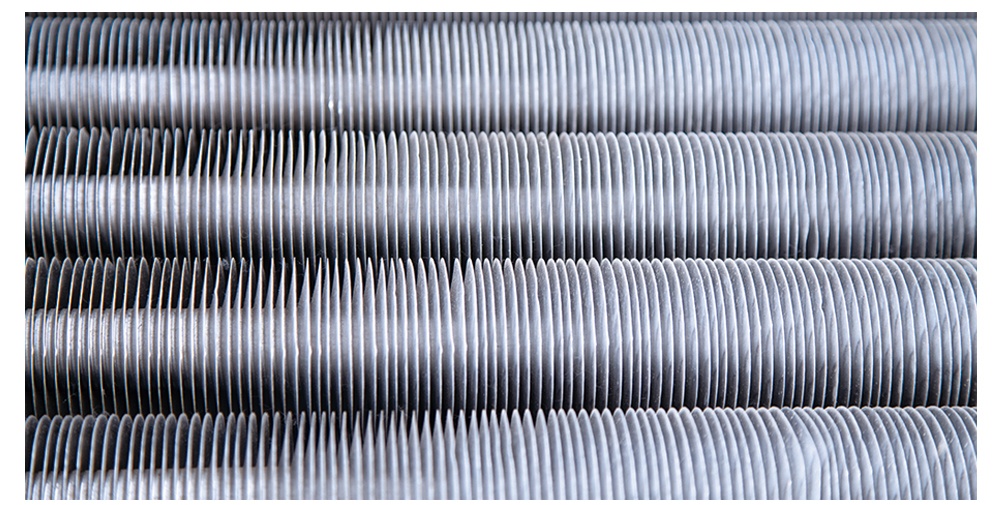

Hot liquid material enters the coil inlet, shown in red. Heat from the process fluid is dissipated across the coil surfaces and transferred to the fins. The air humidification pre-cooling system consists of an evaporative wet curtain located on the side of the coil to thoroughly moisten. Ambient air is drawn into the unit by a ventilator located at the top. And flow through the evaporative wet curtain plate. As the air passes through the evaporative wet curtain, the humidity increases and the dry bulb temperature decreases (only a few degrees of temperature difference from the wet bulb). After that, the pre-cooled air flows over the surfaces of the coils and fins, and the heat removal capacity of the unit is significantly improved. The heat of the process fluid is transferred to the air. and then released into the atmosphere. The cooled liquid flows out of the unit through the coil outlet. As shown in blue.

CASEN ADIABATIC AIR COOLER ADVANTAGES

Intelligent Control of Fan Speed and Wetting

(1) Water conserved by the volume control

(2) Very low energy consumption using Electronically Commutated (EC) motors/fans

(3) Very low water consumption with a high dry operation switching

Optimal Adiabatic Cooling Delivery System

(1)Maximum adiabatic efficiency

(2)Plume-free

(3)No water circulation

(4)System checked for aerosol output

(5)Automatic draining

(6)Dry cooling coil

(7)No spraying

(8)No water treatment required in most cases

Multifunctional Use of Humidification Pads

(1) Easily removable for additional dry operation capacity

(2)Reliable adiabatic-cooling delivery system

(3)Protects coil from dirt and debris

Integrated, Intelligent Control

(1)Wired ready to use

(2)EC motors with a built-in fan speed controller

(3)Motor Management step controller for fan cycling

Installation

(1)Easily rigged by crane thanks to easily accessible lifting lugs

(2)Quick and easy installation

(3)Optimal distribution of forces

(4)Rigid structure, resistant to deflection

PROJECT CASES AND WORKSHOP