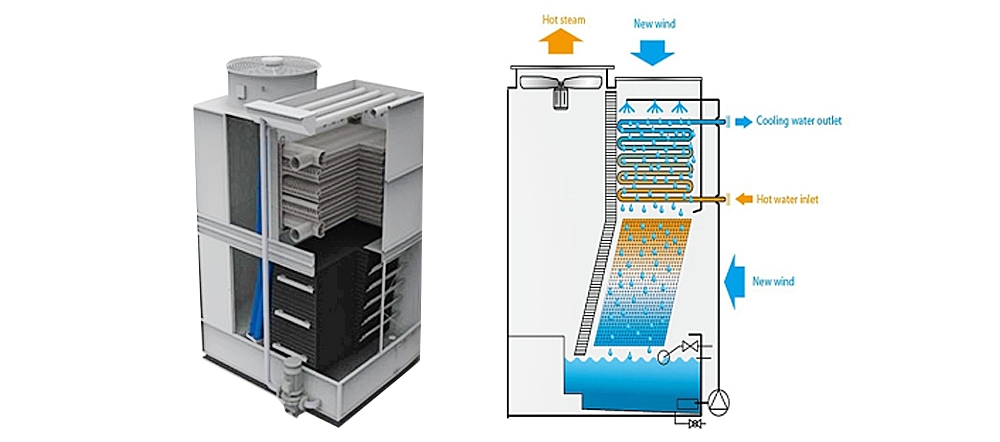

PRINCIPLE OF OPERATION

Closed cooling tower is a heat exchanger between air and water/process fluid, and it can reduce the circulating water/process fluid temperature in heat exchange coil.

Closed cooling tower can be widely used to different fields of industry and HVAC.

Different applications need different types closed cooling tower, such as crossflow type and counterflow type.

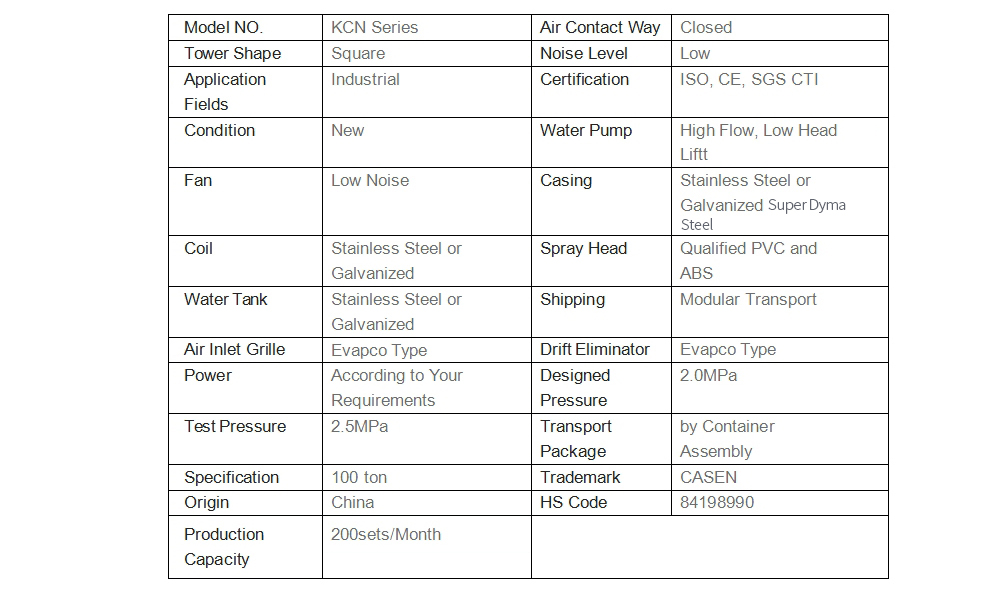

BASIC LNFO

Original Factory High Efficiency Closed Cross Counter-Flow Cooling Tower

PRINCIPLE OF OPERATION

KCH series closed circuit cooling tower is designed with a combined multi-modular configuration, which uses condensing coil and PVC fill for heat transfer. The principle is addressed like this: Water is pumped from water basin and distributed over the fill. Air is induced by axial fan through the fill to make water evaporating and cascading downward the coil. The coil rejects heat through both evaporative cooling through fresh air stream and sensible cooling using the precooled recirculating spray water. And the heat exchange on coil surface is mainly sensible heat exchange which reduces evaporation load and minimize the tendency to form scale on the coil.

The remaining water falls to the cooled water basin where it is recirculated by pump to the upper water distribution system and back down over the fill and coil.

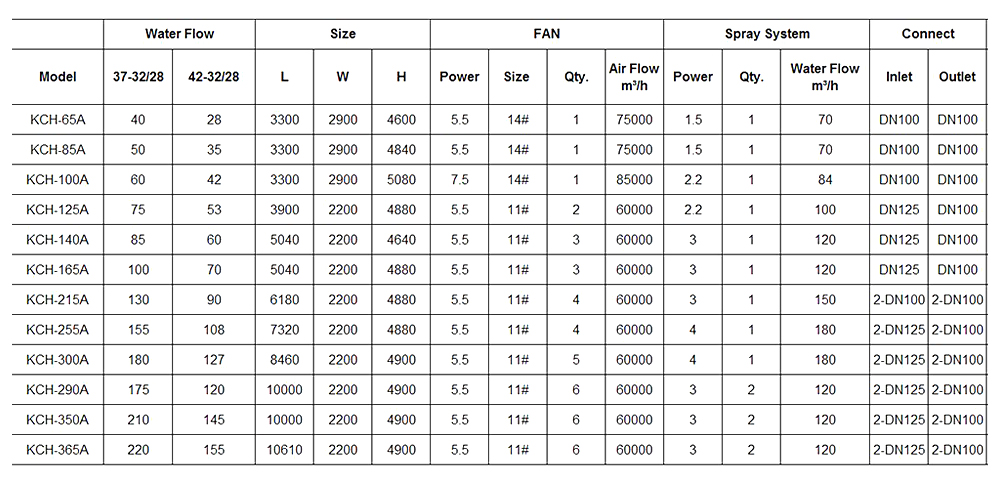

TECHNICAL DATA

ADVANTAGES

ADVANTAGES

Eco-Friendly, Suitable to Low-Charge Ammonia System

•Single equipment capacity range 500RT to 5000RT

•Modular cells structure design, suitable to container shipping

•Factory assembled for maximal installation convenience

•Optimized structural design, Anti scaling, Energy and water saving

•Larger door and access easy for inspection and maintenance

•Special customized axial-flow fans and pumps, maintenance free

•Reliable Driven System, WEG/Siemens/TECO fan and pump motors

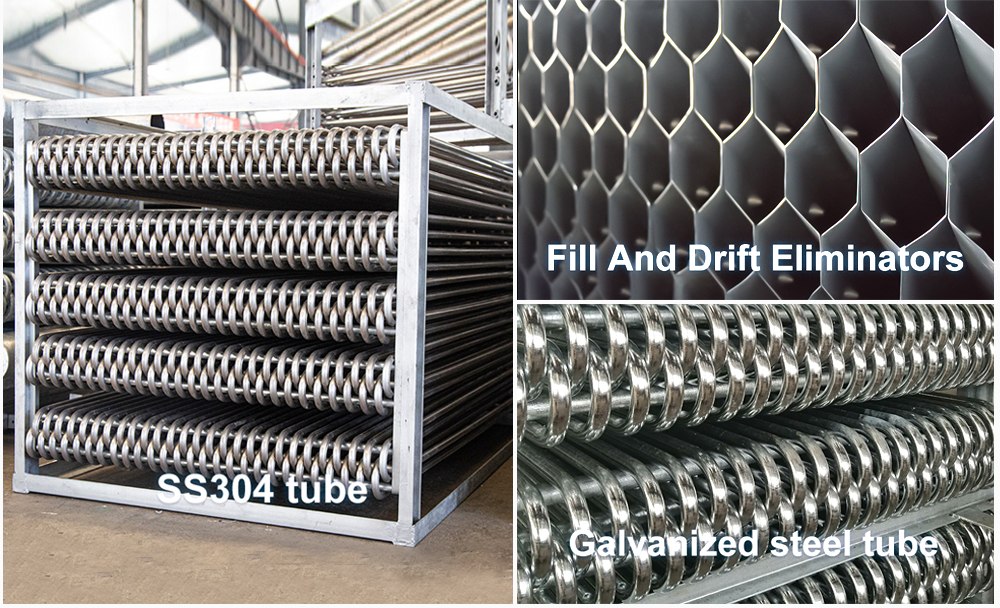

•Multiple corrosion resistant material optionable

•Personal customization solution for automatical control, low noise, energy saving, anti freeze etc.