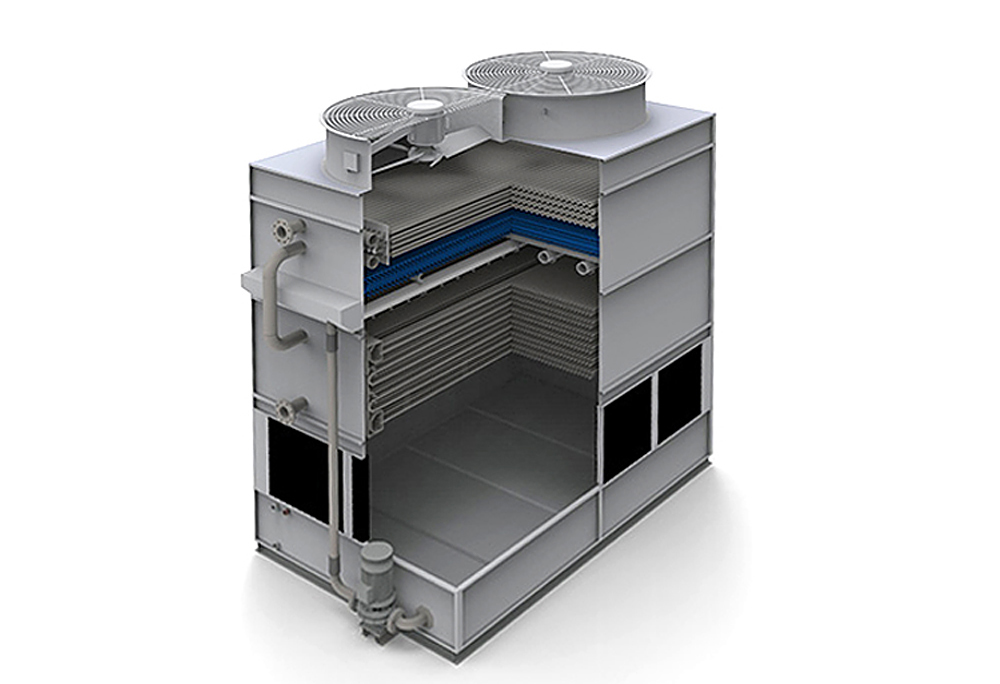

KEJ-HYBRID TYPE EVAPORATIVE CONDENSER

KEJ evaporative condenser is a hybrid type condenser with fin tube unit. It is designed for the water saving and plume abatement. And It can also reduce the evaporation to minimize the tendency of furring on the coil and following problems. It can can operate under dry model while low load.

Key Benefits

100% heat rejection guarantee

High temperature resistance

Reliable

Compact

Anti freezing

KEJ Characteristics

Precooling fin design, axial fan, induced draft

CTI Standard STD-201(21) Coil Design

Capacity range 100 - 3000KW(For single cell models, nominal R717 KW, suitable to container delivery)

Typical Applications

Suitable for serious water shortage area

Suitable for high temperature steam condensation

Limited plan area installations

Indoor installations

Dry operation in winter

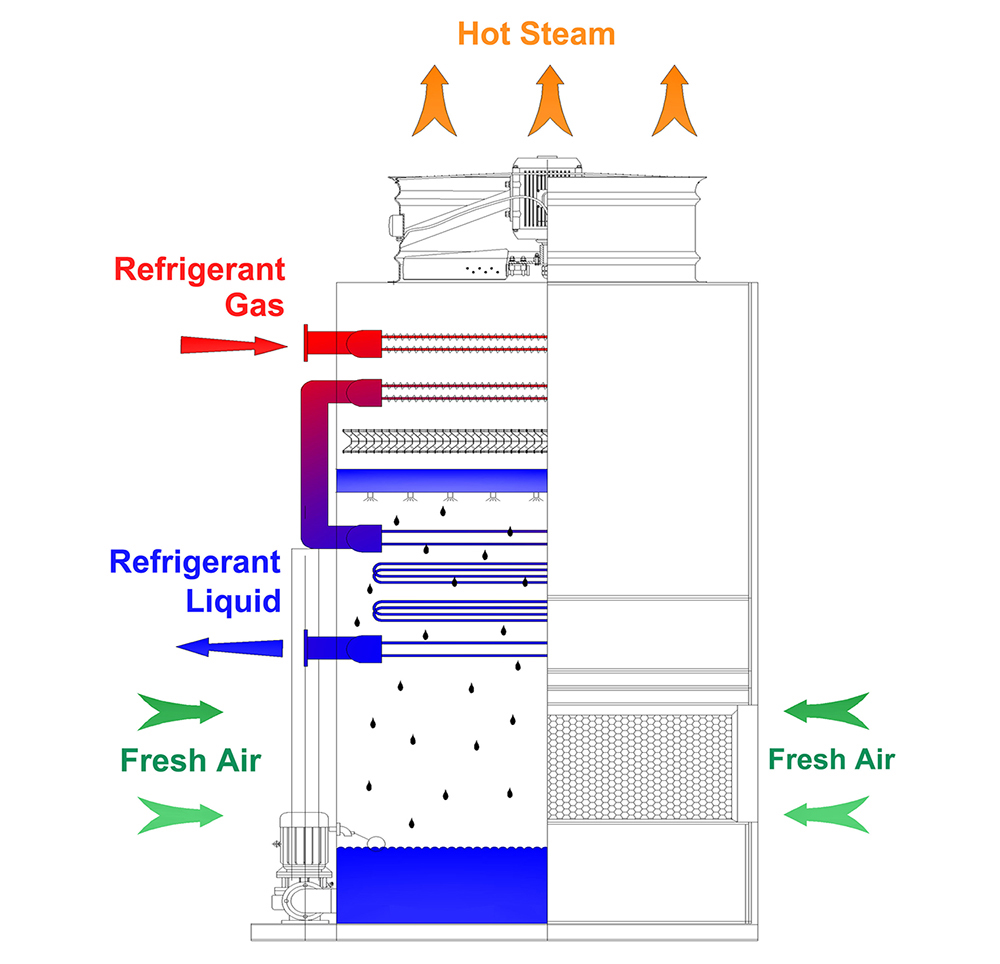

PRINCIPLE OF OPERATION

In the KEJ evaporative condenser, the fin tube unit is positioned above drift eliminator and under the fan. The process gas goes through the fin tube unit at first, then through the below coil part. A portion of the load is dissipated to the atmosphere through the tube walls and fins through sensible heat transfer at the fin tube unit, so less heat needs to be rejected at the coil part, that means less water evaporation. And the gas is condensed to liquid at this process.

Water is pumped from bottom basin and sprayed over the below coil. At the same time, ambient air is induced by axial fan to coil surface and fin tube surface. On the coil surface, enough latent heat and sensible heat is exchanged between air and water, that let process gas give up heat and condensed to liquid. Then the hot and saturated air is drawn through the drift eliminator and fin tube, and the possible plume will be abated by fin tube, then discharged into the atmosphere. The unevaporated water falls into the basin and goes to the recirculation again.