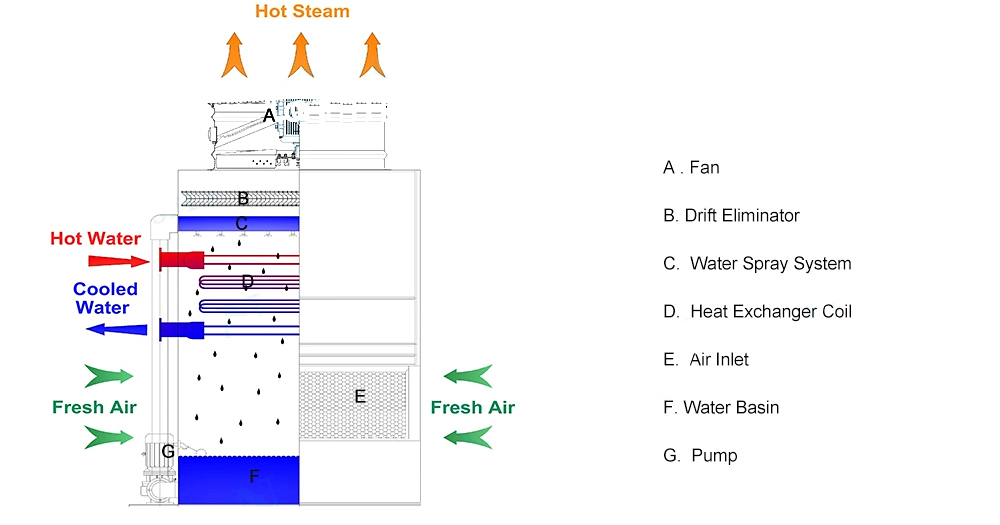

PRINCIPLE OF OPERATION

Warm water from the heat source is pumped to the water distribution system at the top of the tower. The water is distributed over the wet deck fill by means of large orifice nozzles. Simultaneously, air is drawn in through the air inlet louvers at the base of the tower and travels upward through the wet deck fill opposite the water flow. A small portion of the water is evaporated which removes the heat from the remaining water. The warm moist air is drawn to the top of the cooling tower by the fan and discharged to the atmosphere. The cooled water drains to the basin at the bottom of the tower and is returned to the heat source. The vertical air discharge of the KCN design and the distance between the discharge air and fresh air intakes reduces the chance of air recirculation, since the warm humid air is directed up and away from the unit.

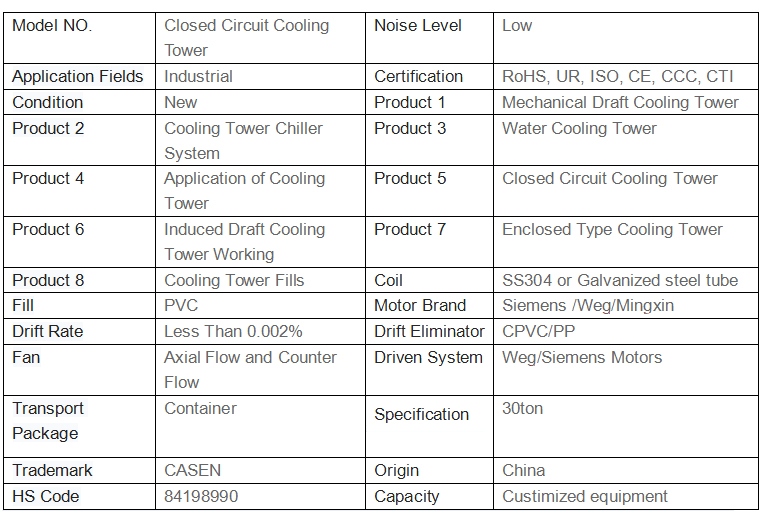

BASIC LNFO

Original Factory High Efficiency Closed Circuit Counter-Flow Cooling Tower

SCHEMATIC DIAGRAM

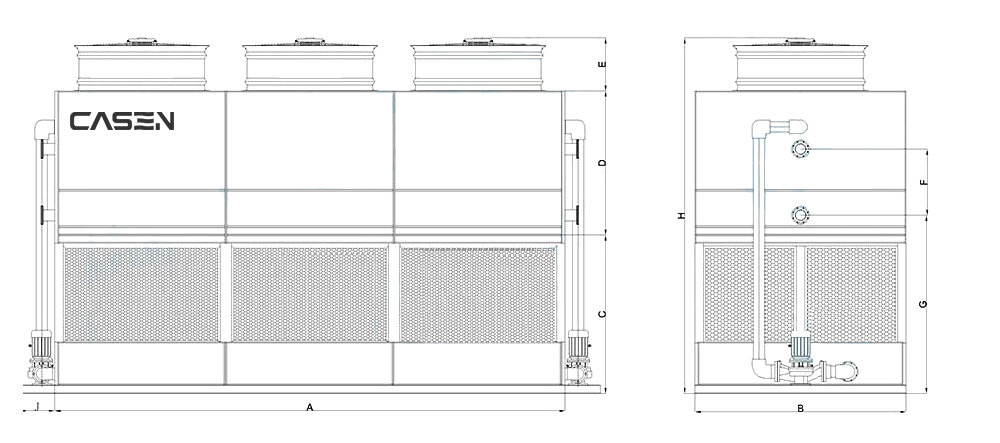

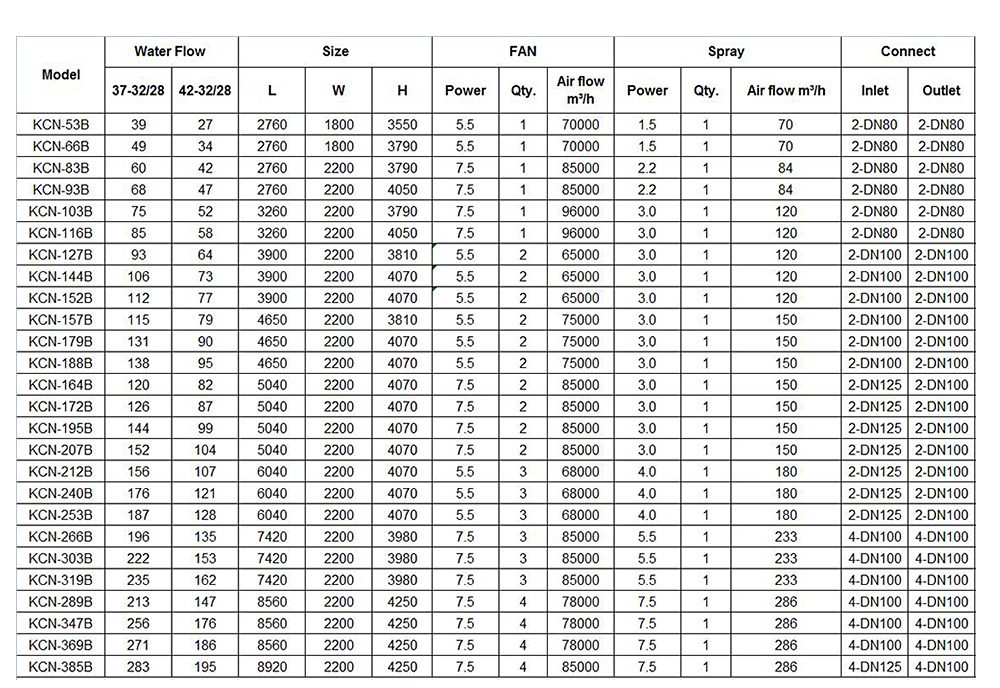

PARAMETER SHEE

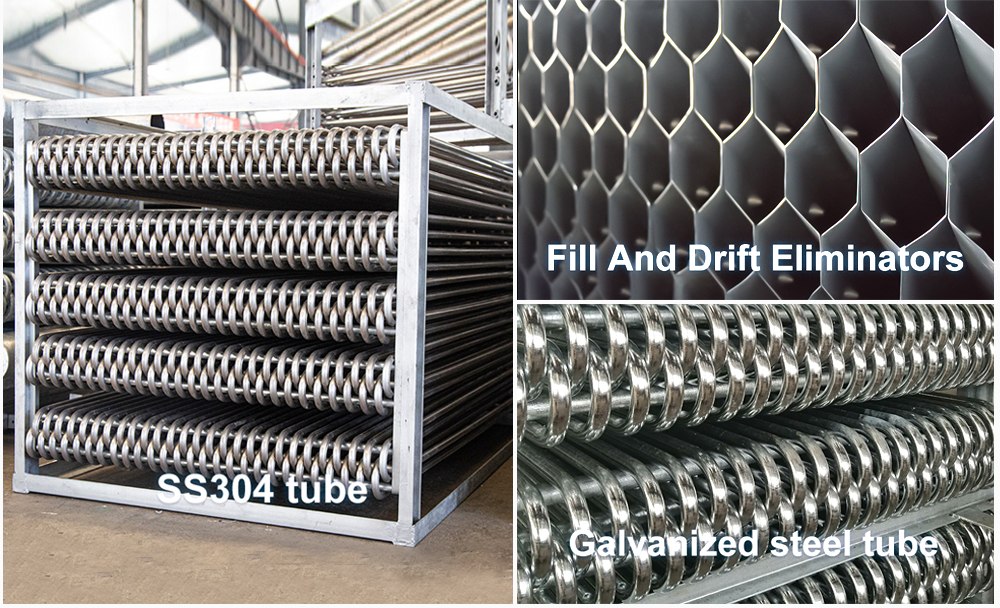

DETAIL PRESENTATION

COUNTER FLOW TYPE COOLING TOWER ADVANTAGES

a. Counter flow Induced Draft, Eco-Friendly Type.

b. With large heat exchange coil, 100% heat rejection capacity guarantee.

c. Repair and maintenance cost saved as no fill inside. (No need to replace the fill during the service life)

d. Anti scaling and easy maintenance, as no infill inside and the infill part is much easy scaling during operation.

e. More compact and closed structure, equipped with Evapco type air inlet grille, good effect of preventing dust and sand, and anti UV.

f. Equipped with Evapco type drift eliminator, lower drift loss, water saving and less scaling.

g. All driven device are famous brand, top class energy efficiency rating, energy saving and reliable.