PRINCIPLE OF OPERATION

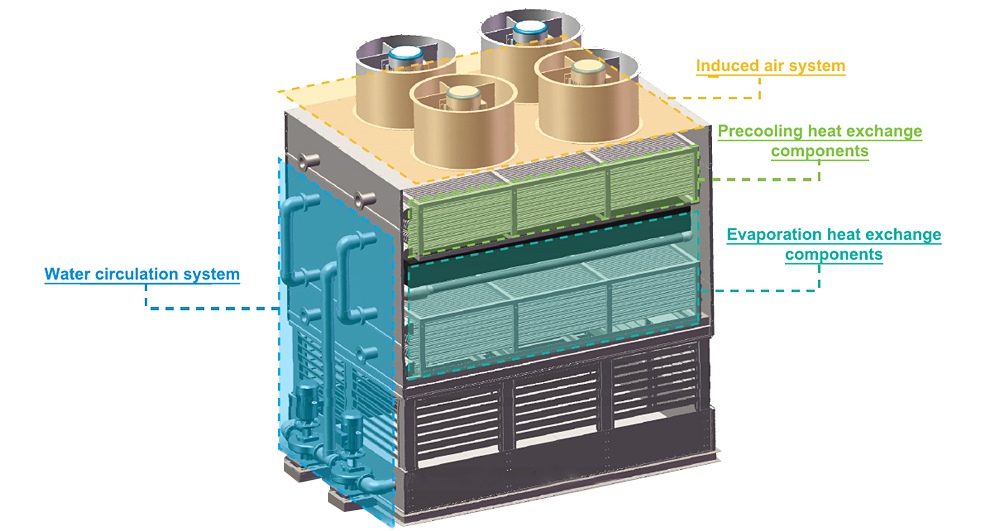

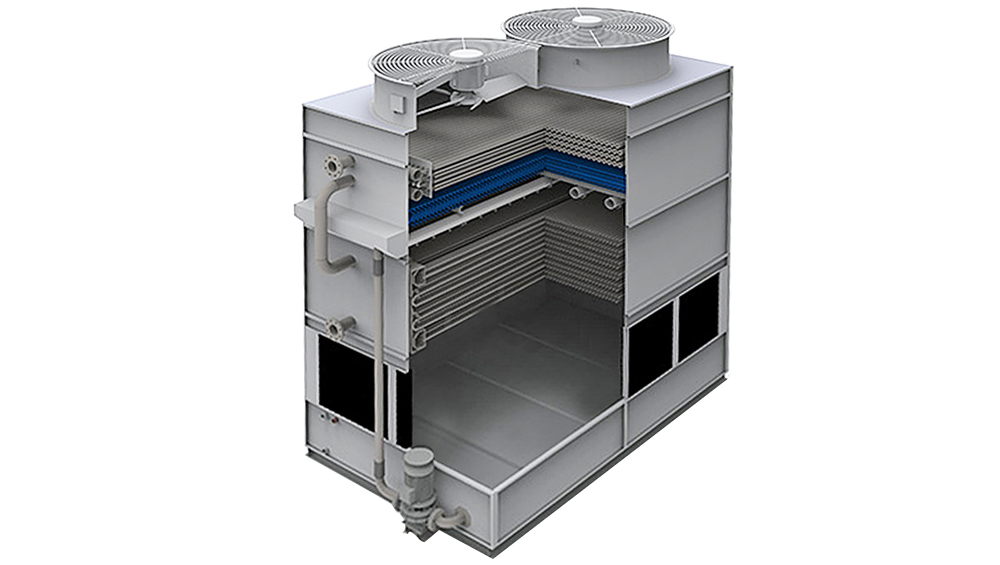

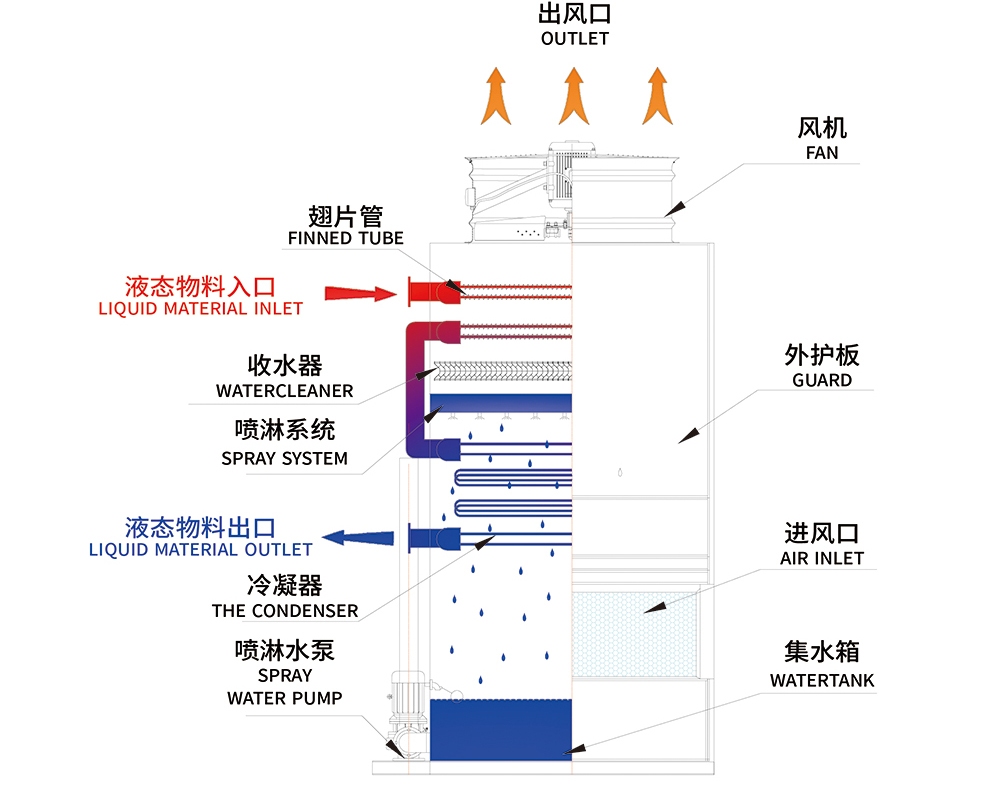

KCJ compound closed cooling tower is cooled for the first time by the wind through the finned tube, and then the heat is replaced by the spray water from the coil by the latent heat of vaporization, and then the heat is discharged by the top fan. The air intake form is the bottom air intake, and the reverse alternating shape of the falling spray water, and because of the Pre-coling fins of the finned tube, it is called the compound countercurrent tower. It consists of pre-cooling heat exchange component, evaporative heat exchange component, water circulation system and induced air system.

TECHNOLOGICAL ADVANTAGE

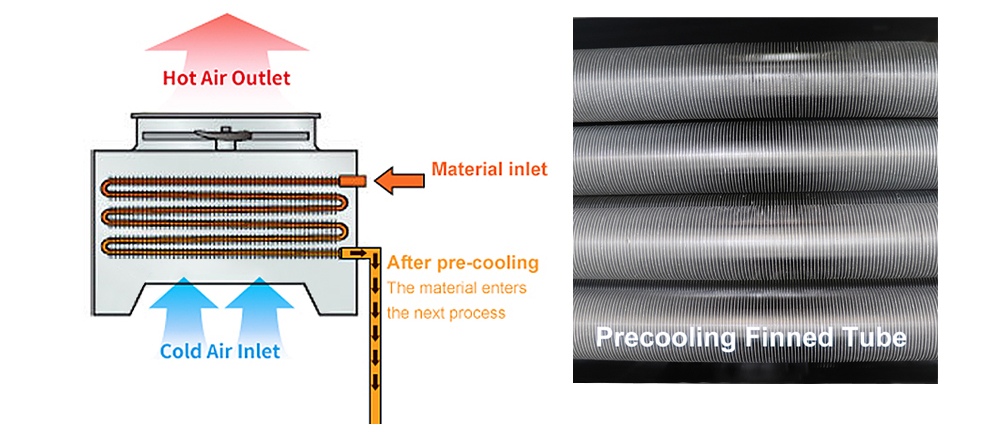

Precooling technique

The high temperature liquid is pre-cooled before cooling, and the high temperature liquid can be cooled by cooling the wet air discharged from the cooling tower coil before discharging into the atmosphere with large air volume and large temperature difference.

This technology can achieve three purposes

① The cooling effect of the cooling tower is improved, and the heat transfer effect has been proved to be increased by more than 10%;

② The scaling phenomenon on the outer surface of the coil is slowed down, and the service life of the equipment is improved;

③ The use of natural air cooling saves energy.

1. Scaling mitigation technology

The cooling medium enters the cooling coil after pre-cooling, and the temperature decreases after pre-cooling, which avoids the phenomenon that water is easy to scale at high temperature to the maximum extent, and slows down the scaling speed on the outer surface of the coil. The water distribution of the heat transfer surface is increased, which can prevent the accumulation of scale during the evaporation of water.

2. Dry winter operation technology

Due to the application of cooling fin components, the performance of the equipment is guaranteed during dry operation in winter, and the natural strong cold air energy in nature is used for heat exchange, which truly achieves the effect of water saving and energy saving.

•With fin tube for high temperature fluid cooled by air only in advance

•It is designed for the water saving and plume abatement

•It minimizes evaporation

•Reduce the scale on the coil

•It can be operated under dry model while low load.

•Modular cells structure design, suitable to container shipping

•Factory assembled for maximal installation convenience

•Optimized structural design, Anti scaling, Energy and water saving

•Special customized axial-flow fans and pumps, maintenance free

•Reliable Driven System, WEG/Siemens/TECO fan and pump motors

•Multiple corrosion resistant material optionable

•Personal customization solution for automatical control, low noise, energy saving, anti freeze etc.

KCJ series of high-efficiency composite closed cooling tower is based on thermodynamics, heat transfer principle, the use of evaporative air cooler and air-cooled condenser combined with the heat transfer mechanism, the use of surface heat transfer of mixed-flow technology and gradient heat transfer energy-saving technology, is the latest generation of high-tech, high-performance and high-quality heat transfer equipment.

In the KCJ series of composite closed cooling towers, the finned tube units are located above the water separator and below the fan. The process fluid passes first through the finned tube unit and then through the coil section below. A portion of the load is dissipated to the atmosphere through the walls and fins via sensible heat transfer at the finned tube units, so less heat needs to be removed in the coil section, which means less water evaporates. In this process, the hot liquid is pre-cooled.

Water is pumped from the bottom basin and sprayed on the coils below. At the same time, axial fans introduce ambient air to the coil surface and finned tube surface. At the coil surface, enough latent and sensible heat is exchanged between the air and water to cause the process fluid to give off heat and cool down. The hot, saturated air is then drawn through the water separator and finned tubes, and the potential smoke plume is attenuated by the finned tubes and vented to the atmosphere. The unevaporated water falls into the basin and re-enters the recirculation.

FEATURE

1. With fin tube for high temperature fluid cooled by air only in advance

2.It is designed for the water saving and plume abatement

3. It minimizes evaporation

4.Reduce the scale on the coil

5.It can be operated under dry model while low load.