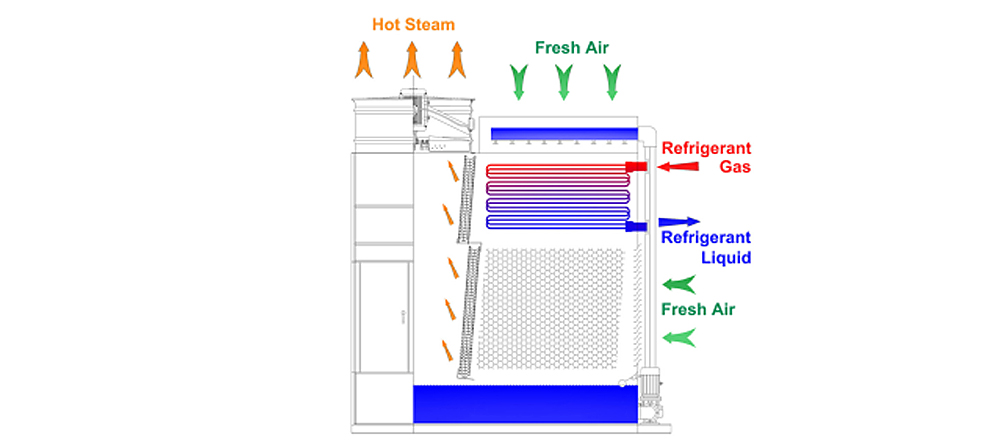

KEF- CROSS FLOW TYPE EVAPORATIVE CONDENSER

KEF evaporative condenser is a combined flow evaporative condenser and the PVC fill can cool the industrial process fluid effectively.

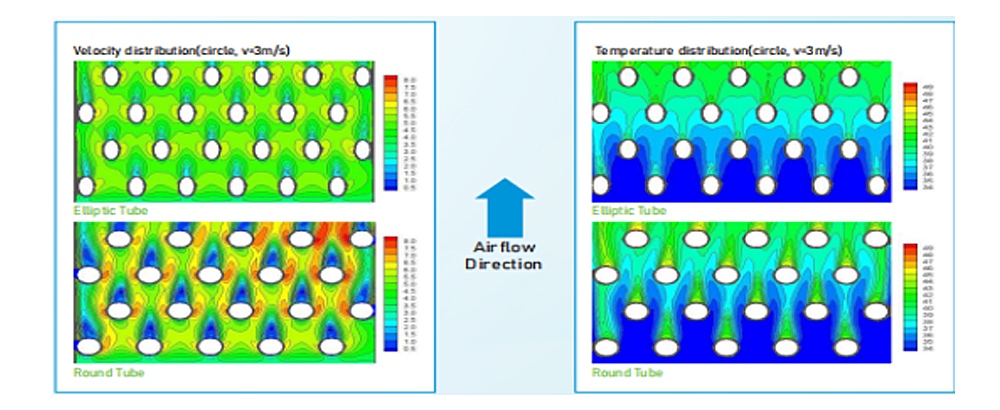

A special coil design is utilized to reduce the air pressure drop through the unit while maximizing tube surface area and increasing its heat transfer capabilities.

Key Benefit

100% heat rejection guarantee

Reliable

With fill cooling, cost effective

Large maintenance space

KEF Characteristics

Cross flow, axial fan, induced draft

CTI Standard STD-201(21) Coil Design

Capacity range 100 - 3000KW(For single cell models, nominal R717 KW, suitable to container delivery)

Typical Applications

Installation require a single air inlet

Indoor installations

PRODUCTS-KEF EVAPORATIVE CONDENSER

KEF evaporative condenser is a combined flow evaporative condenser and the PVC fill can cool the industrial process fluid effectively.

A special coil design is utilized to reduce the air pressure drop through the unit while maximizing tube surface area and increasing its heat transfer capabilities.

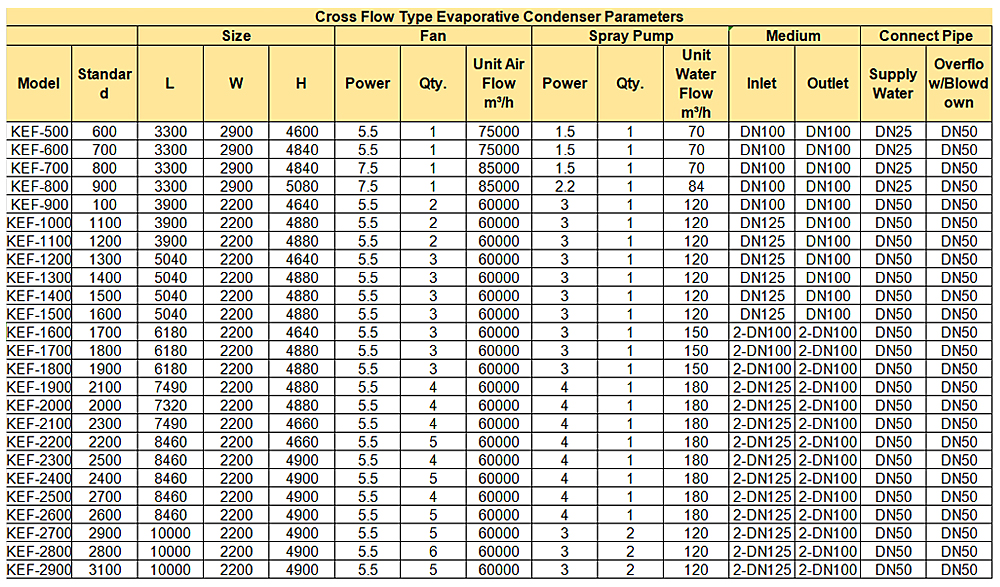

CROSS FLOW TYPE EVAPORATIVE CONDENSER PARAMETERS

DETAIL

1. AXIAL FAN

Particularly suitable for operation at high altitudes and extreme temperatures. Direct drive axial fan with carbon fiber blade, angle index can be adjusted if needed.

Siemens / WEG brand motor

Protection class IP55/IP56, insulation class F

Explosion- proof motor available

PRODUCT FEATURES

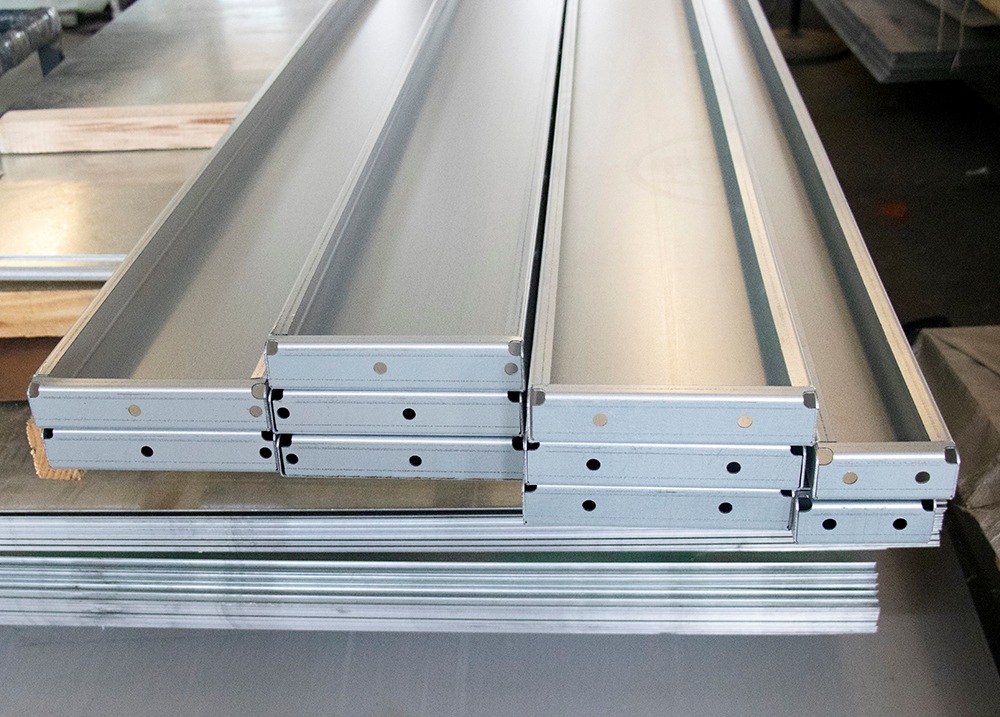

2. Casing Materials:SuperDyma Steel

Optional material: Gl, SuperDyma,SS304, SS316

*The corrosion resistance is 10-20 times that of hot-dip galvanized steel, and the notch corrosion resistance is particularly excellent.

* With High hardness, good bonding strength of coated steel plate, good scratch resistance and formability

* It is suitable for applications with high corrosion resistance and high forming requirements such as industrial equipment, construction, photovoltaics, and automobile parts. It has unique advantages in alkaline environments.

Salt spray test: SuperDyma steel vs Ordinary steel plate

Super Dyma Steel shows 5 to 10 times the corrosion resistance compared to galvanized steel sheet on flat surfaces.

In addition, Super Dyma Steel shows equal or greater corrosion resistance than galvalume on flat surfaces.

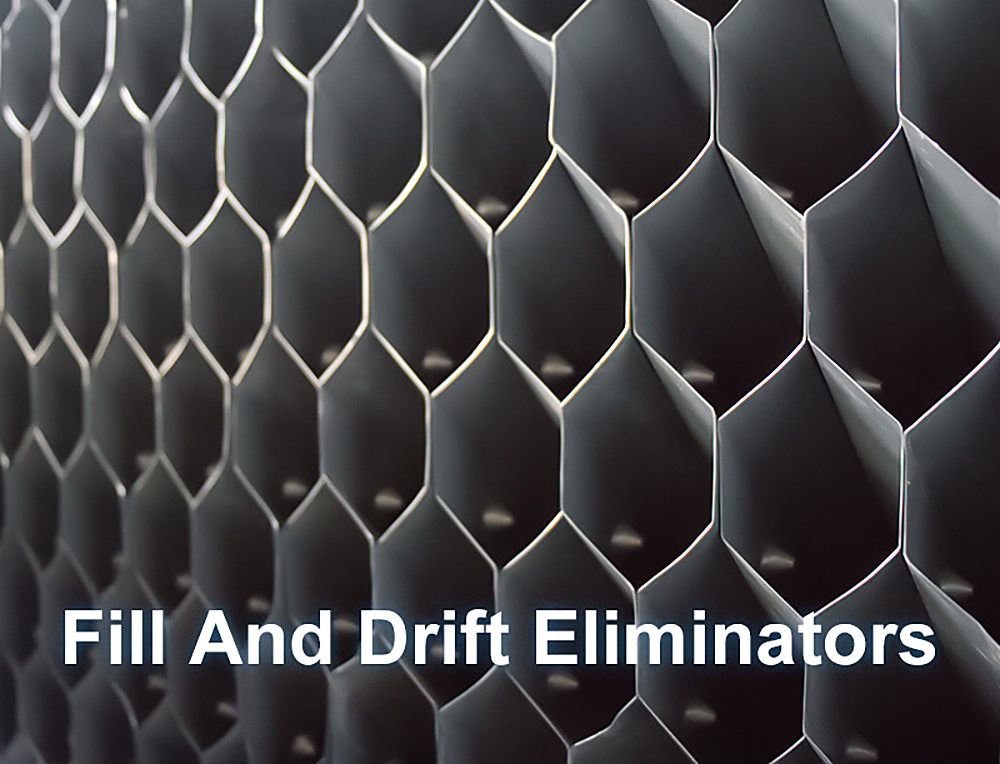

3. FILL

Fills are designed to with the most suitable flame retardant PVC material to give the best thermal performance, impervious to rot, decay and biological attack.

Widest range of flute geometries PVC with 42% oxygen index, fire classification M2

Working temperature 65

Thickness: 0.3 -0.4 mm

COIL

a. Continuous serpentine shape and oval tube design,improve the tubes air to water interface for increased heat transfer efficiency

b. Whole stainless steel 304 materials,with superior corrosion resistance

c. If needed,the coil is filled with nitrogen to maintain pressure when shipped,keep the coil dry and check the tightness

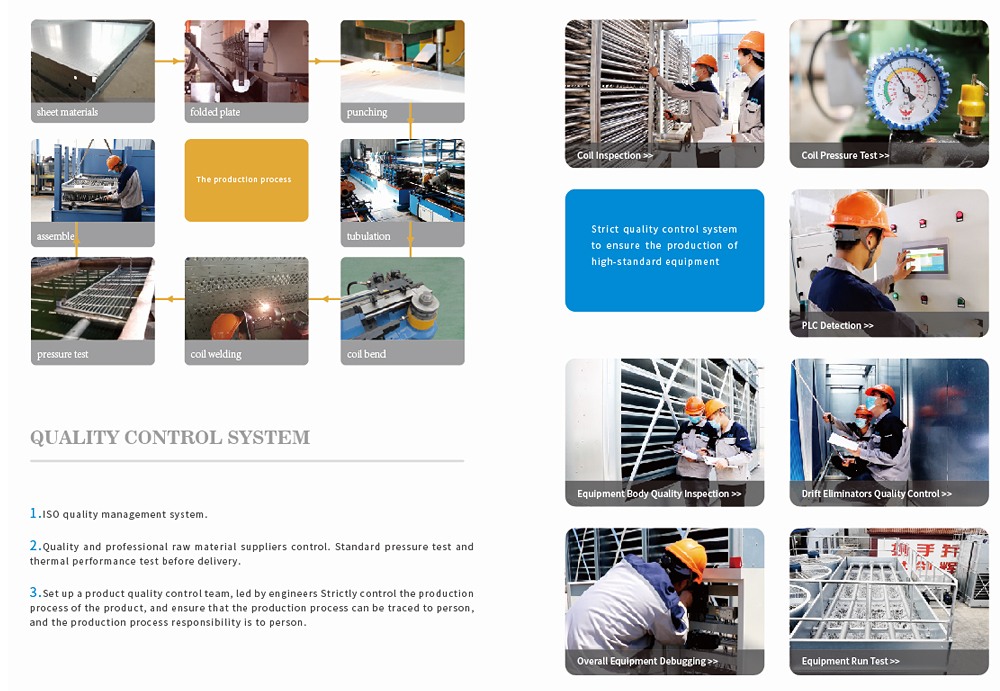

STRICTIY QUALITY CONTROL

CASE