V-TYPE(DRY)AIR COOLER

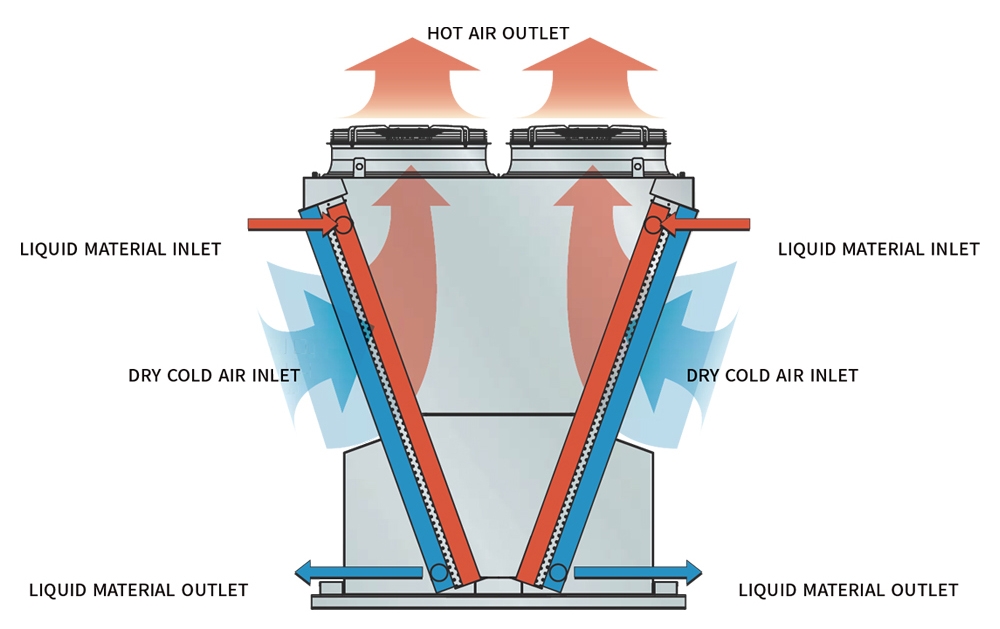

The air cooler uses ambient air as the cooling medium, and traverses the finned tube to cool or condense the high-temperature process fluid in the tube, referred to as "air cooler", also known as "air-cooled heat exchange"

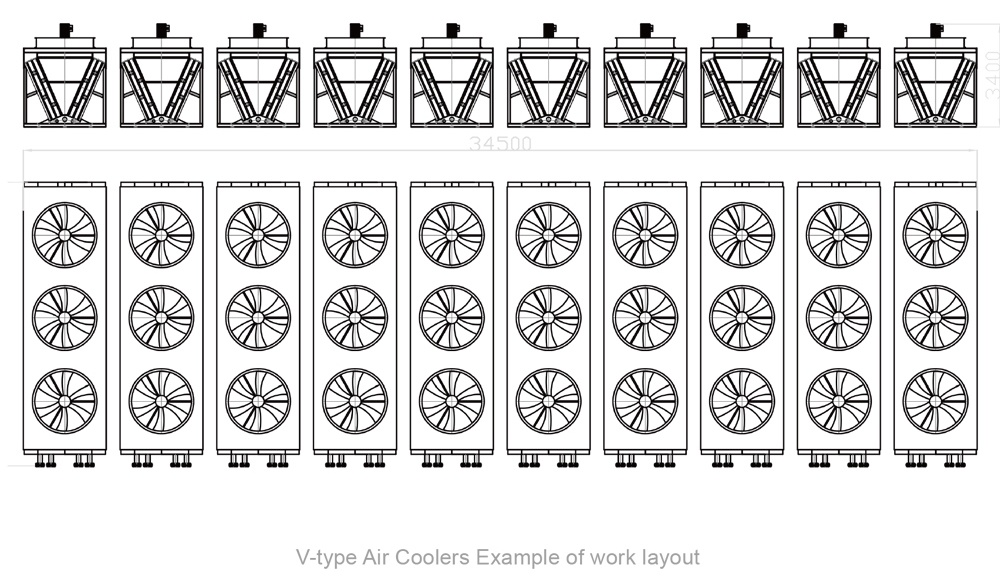

V-type air cooler is the most widely used heat exchange equipment for condensation and cooling in petrochemical and oil and gas processing and production. V-type air cooler is generally composed of tube bundles, tube boxes, fans, shutters and the main components of the structure. The structure is V-shaped, which has the characteristics of small footprint, high heat exchange efficiency and convenient transportation. The V-shaped angle is generally 45°C or 60°C.

Optimized Structure, Suitable to Container Shipping

Large Air Volume, High Effective in Heat Transfer

Low Energy Saving By High Efficiency Motors

Top Quality Fin Tube Coil, Compact Structure

Water Saving, Low Noise, Cost Effective

KEG CHARACTERISTICS

Individual Fan Drive System, Super Low Sound Axial Fan, Induced Draft

CTI Standard STD-201(21) Coil Design

Capacity Range100 - 3000KW(For Single cell models, nominal R717 KW, suitable to container delivery)

TYPICAL APPLICATIONS

Suitable for serious water shortage area

Suitable for areas with strict noise requirements

Suitable for cold regions

Limited plan area installations

Indoor installations

Dry operation in winter time

Hot liquid material enters the coil inlet, shown in red. Heat from the process fluid is dissipated across the coil surfaces and transferred to the fins. Ambient air is drawn into the unit by a top-located fan and flows over the coil surfaces. Heat from the process fluid is transferred to the air and then vented to the atmosphere. The cold liquid material flows out of the unit through the coil outlet, as shown in blue in the figure.

what is the advantage of dry cooler

Dry cooling removes heat from a system using sensible heat rejection. The lack of water and any need for water treatment greatly reduces the required maintenance for this type of cooling equipment.